- Article

A Transient Two−Phase Productivity Forecasting Method in Fractured Nanoporous Shale Gas Reservoirs

- Ruihan Zhang,

- Siliang He and

- Liehui Zhang

- + 2 authors

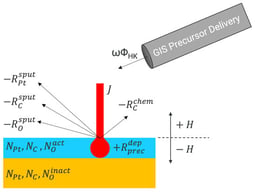

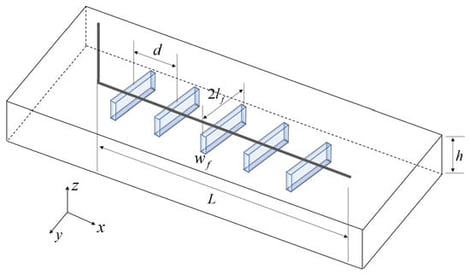

Hydraulic fracturing is a critical technology for developing shale gas reservoirs, which are typical natural nanoporous media. However, the complex two−phase flow induced by fracturing fluid retention and the strong interference among hydraulic fractures introduce significant uncertainties to productivity forecasting. To address these challenges, this study proposes a transient productivity forecasting method to characterize fluid transport in fractured nanoporous media. This method introduces a gas−water two−phase pseudo−pressure function to reconstruct the flow equations, utilizing micro−segment discretization and the principle of superposition to accurately characterize pressure drop interference among fractures, enabling rapid dynamic productivity forecasting under realistic well trajectory conditions. The investigation reveals that while increasing fracture count, half−length, and permeability enhances productivity, these improvements exhibit significant diminishing marginal returns, indicating the existence of optimal economic thresholds for these engineering parameters. Conversely, elevated water saturation, skin factor, and stress sensitivity lead to a decline in productivity. Analysis of flow interference demonstrates that fractures at the wellbore extremities contribute significantly higher production than those in the central section due to reduced interference, while deviations in the wellbore trajectory further exacerbate production heterogeneity. Field application confirms that the proposed method achieves reliable production history matching under realistic well trajectories and accurately captures the typical three−stage production characteristics of shale gas wells, providing a robust basis for Estimated Ultimate Recovery (EUR) assessment and fracturing design optimization.

17 February 2026

![Comparison of demagnetisation behaviour of Sm2TM17 production scrap (A) and the reference material (B). Measurements were taken at a range of temperatures from 25 to 200 °C. (A) Reprinted from Ref. [23].](https://mdpi-res.com/cdn-cgi/image/w=281,h=192/https://mdpi-res.com/nanomaterials/nanomaterials-16-00263/article_deploy/html/images/nanomaterials-16-00263-g001-550.jpg)